Fabric-Infrastructure

The capabilities of SRI KRISHNA SPINNING & WEAVING MILLS PVT. LTD. has increased by leaps and bounds over the last decade.The new millennium has ushered in an age of technology, speed and precision which has redefined the future of businesses in the ever-changing landscape of the textile industry and we are fully equipped with the latest machines to meet these challenges. We ensure best optimization of resources across the production processes using machines that are best-in-class and have been acquired from the most reputed manufacturers worldwide. Our team of managers, technicians and work force are specially trained to run and maintain these machines. Our capability, capacity, efficiency and quality are driven by the latest and most technologically advanced machinery & processes.

Our state of the art machines for various fabric processing processes are summarized below.

| Process | Machine |

|---|---|

| Singeing & De-sizing | Osthoff, Germany |

| Bleaching | Benninger CBR, Switzerland |

| Mercerizing | Cadena Hot Mercerizing Range Goller Textilnaschinen GmbH, Germany |

| Dyeing | Open Width Cold Pad Dyeing System Type Bicoflex – Ramisch Kleinewefer |

| Emerizing/Microsanding | Lafer – Italy, “Carbosint” Diamond emeries |

| Rotary Printing | Pegasus 16 Colour Rotary Screen Printing Machine – Stork Prints B.V.,Netherlands & Stork 10 colour Printing Machine |

| Finishing & Shrinking | Harish Stenter, Dhall Pre-Shrinking Machine |

Loose fibres protruding on the surface of textile goods are singed to remove them. When done to fabrics containing cotton, this results in increased wettability, better dyeing characteristics, improved reflection, no ‘frosty’ appearance, a smoother surface, better clarity in printing, improved visibility of the fabric structure, less pilling and decreased contamination through removal of fluff and lint.

Sirkrishna mills procures its grey fabric from reputed, modern and high capacity looms. As the grey manufacturing process uses sizing agents to improve weaving productivity by increasing weft insertion speeds, it is necessary in our processing facility to desize the greys for optimum wet processing and dyeing.

This first and important stage in fabric processing at Srikrishna Mills is done in state of the art of Osthoff Singeing Machine imported from Germany.

Evenness and reproducibility are of primary importance for fabric dyeing and printing, and we promise our customers nothing less than the best. Our modular scouring/washing and bleaching process is powered by world renowned EXTRACTA, INJECTA, developed by Benninger, Switzerland to ensure that all types of fabric we process are pristine. Additionally, our best in class Benninger washing and bleaching process is highly energy efficient and environment friendly and gives a good absorbent fabric for the next process.

Hot mercerization is a technique pioneered in the 1960’s to speedup and improve the alkili penetration into the fabric core. The Cadena Hot Mercerizing Range manufactured by Goller Textilnaschinen GmbH, Germany at Srikrishna Mills produce fabric that is stronger, smoother, and shinier than regular cotton. Our best in class mercerization process ensures rich color saturation, brilliant and lustrous hues of mercerized cotton fabric enabling us to serve our marquee customers world over.

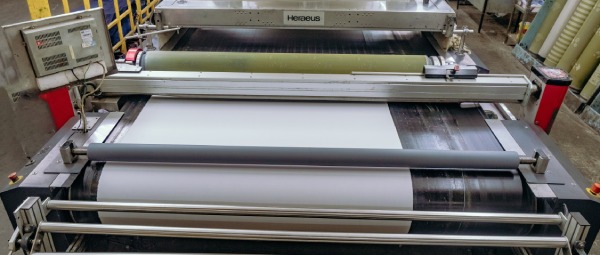

Reactive Dyeing at Srikrishna Mills is done in Ramisch Kleinewefer’s open Width Cold Pad Dyeing System Type Bicoflex. Our 60 thousand metres per day dyeing capacity in cotton and synthetic fabric (rayon, nylon and viscose) is complemented with a quality controlled dyeing process starting from colour preparation to fixation, washing (Ultrawasher) and soaping process (Harish) to provide best in class colour penetration and fastness in all our dyed fabric. Srikrishna Mills also has a Polyster Jet Dyeing machines from Sanjay.

Our dyeing capabilities enable us to serve a wide spectrum of clients and order sizes ranging from small order designerware shades to large orders by international brands.

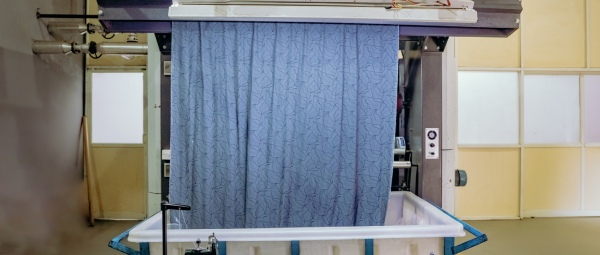

Printing is done on Pegasus 16 Colour Rotary Screen Printing Machine by Stork Prints B.V., Netherlands. Types of printing done are Reactive, Discharge, Pigment, Resist, Khadi, Blotch, Reactive Pigment Blotch, Printing on Yarn dyed shirtings, Seersucker, etc. Our printing capabilities are matched by a excellent design team enabling us to serve a wide spectrum of clients and order sizes ranging from small order designerware shades to large orders by international brands.

World renowned Lafer Sueding machines from Italy ensure a superior sueding effect with no streak. The exclusive ‘Carbosint’ diamond emery developed by 3 MCorporation and its flexible configurations provide Srikrishna Mills with the ability to cater to large orders and several sueding effects.

Finishing & Shrinking are done on Harish Stenter & Dhall Shrinking Machine.